Inconel Alloy 718 (UNS N07718 / W.Nr. 2.4668)Coil Tube

- HOME

- Inconel Alloy 718 Pipes

- Coil Tube

Inconel 718 Coil Tube Supplier

As a leading Inconel tube supplier, RAHUL FERROMETAL manufactures and produces high quality and customized Inconel 718 coil tube.

INCONEL® alloy 718 (UNS N07718 / W.Nr. 2.4668) is a high-strength, corrosion-resistant nickel chromium material used at -423° to 1300°F. The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to postweld cracking, are outstanding.

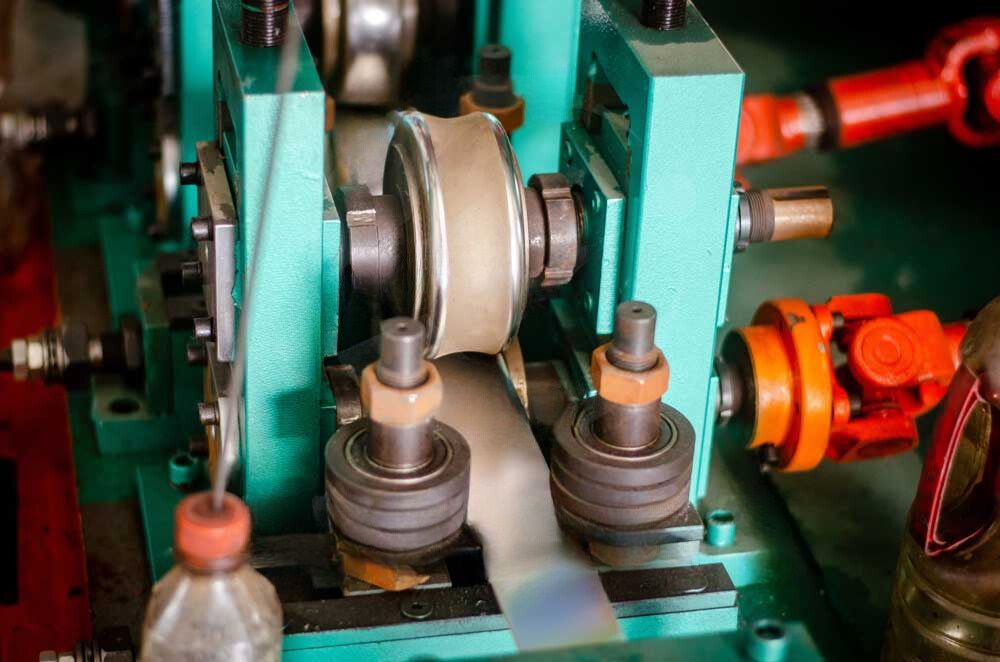

Inconel 718 coil tube is a continuous small diameter Inconel 718 tube manufactured by welding, continuously cold drawing and coiling the Inconel 718 strip. Due to its continuity, we will use bright annealing process to avoid the generation of oxide skin inside the tube. Inconel 718 coil tubes have excellent high temperature resistance and corrosion resistance, as well as good integration. We also provide Inconel 718 seamless coil tube and Inconel 718 welded coil tube for your choice. It should be noted that due to the difference in technology, the length of the Inconel 718 seamless coil tube of the same size will be less than that of the Inconel 718 welded coil tube. Please confirm this with us.

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Inconel 718 Coil Tube

*We will strictly produce Inconel 718 Coil Tube according to the standard

Chemical Composition of Inconel 718

*Chemical Composition According to ASTM B983

Data Sheet

Physical Properties

| Density | g/cm3 | 8.19 | |

|---|---|---|---|

| lb/in.3 | 0.296 | ||

| Melting Range | °F | 2300 - 2437 | |

| °C | 1260 - 1336 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) |

Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Aging Treated | 1034 | 862 | 20 | ... | 40C Max |

*Mechanical Properties According to ASTM B983

Inconel 718 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air