Incoloy Alloy 800HT (UNS N08811)Strip

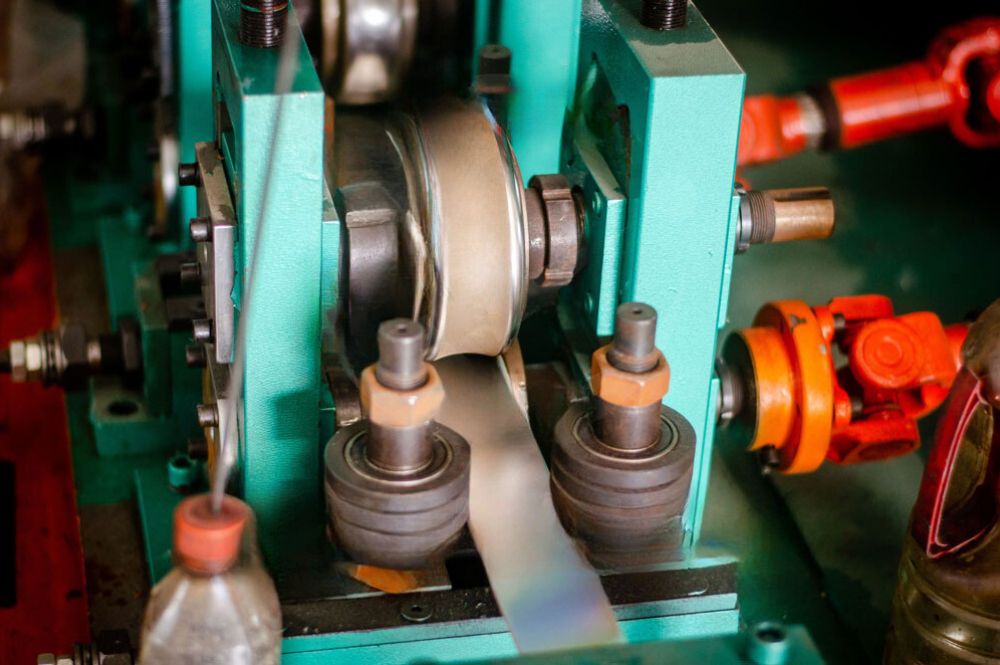

Incoloy 800HT Strip Supplier

As a premium superalloy producer, we offer high value Incoloy 800HT strips.

Incoloy 800HT (UNS N08811) is the highest performing alloy in the Incoloy 800 series. It further improves creep performance and comprehensive performance on the basis of Incoloy 800H. Incoloy 800HT can completely replace Incoloy 800 and Incoloy 800H in the application.

We manufacture Incoloy 800HT strip in strict accordance with ASTM B409 to achieve the best performance of the material. We can achieve high-precision control of material composition, properties and grain size requirements, which sets us apart from many suppliers.

Customized Dimensions

Tolerance according to ASTM B906

*Customized size please confirm with us

Standards for Incoloy 800HT Strip

*As a professional manufacturer, our default standard for Incoloy 800HT strip is ASTM B409. We can also produce according to other standards as per you required.

Edge to be Customized

Chemical Composition of Incoloy 800HT

*Chemical Composition According to ASTM B409

For better creep strength, Incoloy 800HT has very strict requirements on the composition of carbon and aluminum. We adopt the smelting method of VIM+ESR to meet this requirement to the greatest extent.

Data Sheet

Physical Properties

| Density | g/cm3 | 7.94 | |

|---|---|---|---|

| lb/in.3 | 0.287 | ||

| Melting Range | °F | 2475 - 2525 | |

| °C | 1357 - 1385 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) |

Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Annealed | 450 | 170 | 30 | ... | ... |

*Mechanical Properties According to ASTM B409

We do final heat treatment to the Incoloy 800HT strip according to the standard with a minimum temperature of 2100°F (1149°C) and precisely control the grain size of the alloy to ASTM No. 5 or croaser. And many more suppliers don't even know about it. This is our core advantage.

Other Informations

Package

Plastic Bag

Carton Box

Wood Reel

Wooden Pallet

Logistics

By Sea

By Air